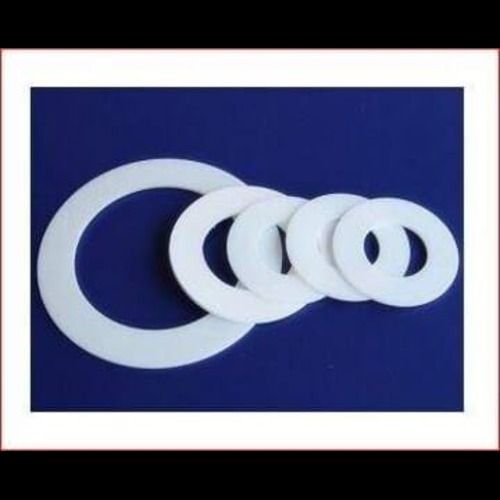

SPIRAL WOUND GASKET

SPIRAL WOUND GASKET Specification

- Product Type

- SPIRAL WOUND GASKET

- Type

- GASKET

- Material

- PTFE

- Specialty

- Waterproof

- Color

- Multiple

SPIRAL WOUND GASKET Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 3 Days

- Main Domestic Market

- All India

About SPIRAL WOUND GASKET

spiral wound gasket is a semi-metallic sealing device constructed by spirally winding a V-shaped metal strip with a soft, non-metallic filler material, creating a flexible and resilient gasket capable of handling high pressure, temperature fluctuations, and misaligned flanges, commonly used in industrial applications like pipelines and pressure vessels; it often includes an outer centering ring and sometimes an inner ring to protect the sealing element from contamination; the metal strip provides strength and recovery, while the filler material ensures a tight seal.

Key points about spiral wound gaskets:

Construction:

A V-shaped metal strip (usually stainless steel) is spirally wound with a soft filler material like graphite or PTFE between each layer.

Components:

Outer ring: A centering ring made of carbon steel, used to properly position the gasket within the flange.

Inner ring (optional): Protects the sealing element from potential damage by the fluid flowing through the pipe.

Sealing element: The spirally wound combination of metal strip and filler material that creates the seal.

Benefits:

High pressure and temperature resistance:

Can handle extreme conditions due to the combination of strong metal and resilient filler.

Flexibility and conformability:

The spiral design allows the gasket to conform to slight flange imperfections.

Good for pressure fluctuations:

Can handle changing pressure conditions without losing sealing integrity.

Wide range of applications:

Used in chemical processing, oil and gas, power generation, and other industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Non Asbestos Cut Gasket Category

Non Asbestos Cut Gasket

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Type : Seals

Specialty : Dust Free

Shape : Various Shapes

Color : Different Available

PTFE READY CUT GASKET

Price 70 INR / Piece

Minimum Order Quantity : 1000 Pieces

Type : Seals

Specialty : Waterproof

Shape : Round

Color : White